SOFLUX Extruder Inline Viscometer - The Only

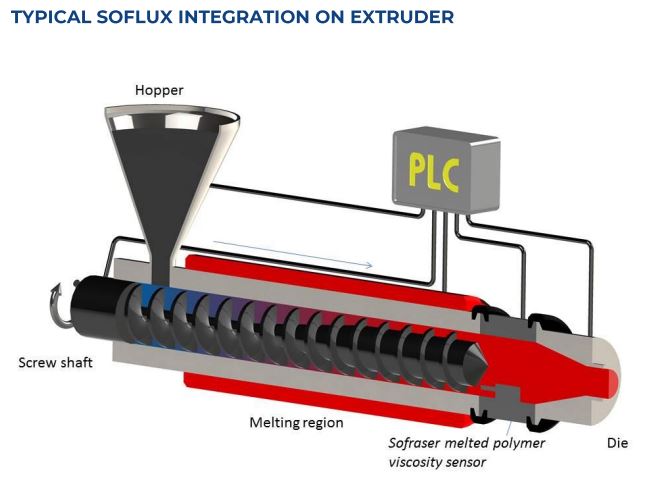

Product Description:The only in-line viscometer in the world designed specifically for extrusion applications, the SOFLUX viscosity sensor is a new vibrating in-line process viscometer with a specialized shape for easy integration into any plastic, polymer or elastomer extruder. It is the ideal solution for monitoring any extrusion process, even the most demanding special compounding, recycling, reactive extrusion.

Product Details

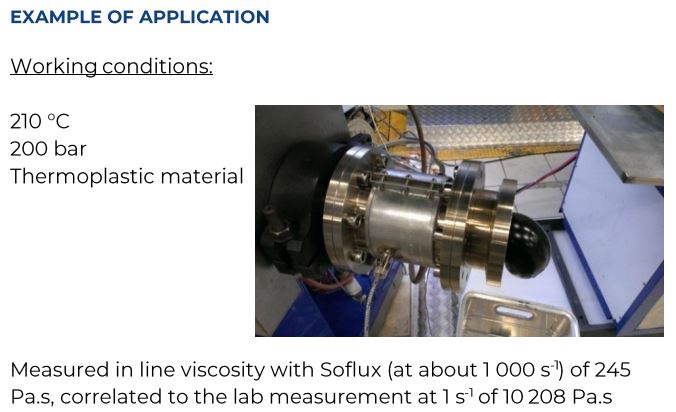

1. Based on the proven sofraser vibration technology: reliable, repeatable and continuous measurement combined with superior quality for permanent production efficiency and higher profitability.

2. The first actual online viscosity measurement of molten polymer: Soflux is installed between the screw and the die to directly measure the viscosity within the flow, avoiding any errors in real time due to the evolution of products outside the process.

3. Easy to correlate: The viscosity of Soflux can be correlated to usual parameters like MFI or intrinsic viscosity (iv) in order to control the extrusion process via analog or digital output.

4. Minimal maintenance: Due to its design, Soflux has no time drift and is easy to clean. Made of 316 stainless steel, it is sturdy and reliable.

Applications

1. Plastics, polymers, elastomers

2.PE, PP, PS, PC, PET, PVC, PA…

3. Food

4. Extrusion, injection

5. Recycling, compounding

Features

1. Viscosity is measured directly in the mainstream

2. Product (without bypass loop)

3. Allows measurement at high extrusion temperatures

4. Designed to measure extremely high viscosity

5. Negligible additional head loss

6. Easy to correlate with conventional parameters such as MFI and Intrinsic Viscosity (IV)

7. Products with viscosity over 10E12Pa.s

8. Withstand high pressure (300bars)

9. Analog and digital outputs

Online Inquiry

Equipment Type

Contact Us

Name:Mr Li

Mob: 18813228250

Tel: 020-84820069

E-mail: h18813228250@163.com

Address: Room 304, Building 2, Zhongheng Commercial Plaza, Qinglian Road, Xinya Street, Huadu District, Guangzhou City, Guangdong Province

Online Service

Online Service